The environmental advantages of natural gas as a motor fuel for vehicles are well known — an order of magnitude lower emissions of fine particulate matter in exhaust gases compared to diesel-powered ICE and 17% (at best) lower CO2 emissions.

Currently the lineup of serially produced vehicles powered by compressed natural gas (CNG) includes 227 models, including 127 truck models, 43 passenger vehicles, 36 special-purpose vehicles, 19 light commercial vehicles and 2 passenger car models (LADA Largus CNG, LADA Vesta CNG).

Meanwhile, for several decades the number of CNG-powered vehicles has been 100–150,000 units, and only in 2022, according to PJSC Gazprom, it reached 260,000 units. At the same time, the number of compressed natural gas filling stations (CNG stations) in the Russian Federation as of 01 January 2022 was only 419 units, the maximum capacity of which does not exceed 2 bcm per year, despite continuous and significant investments of budget funds for the purchase of CNG vehicles and construction of CNG stations.

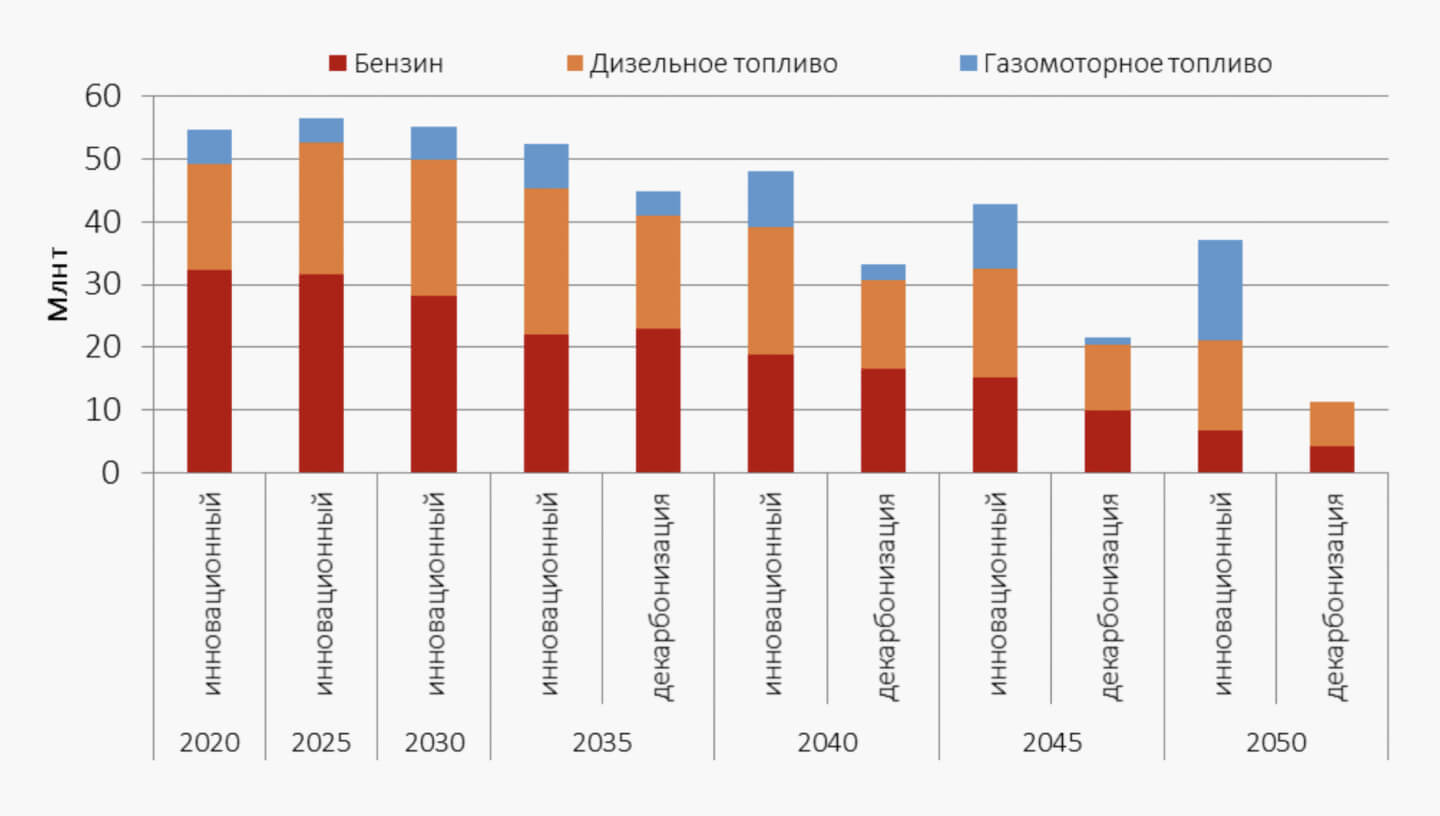

Forecast of motor fuel consumption by type of motor fuel by the Russian vehicle fleet until 2050 (MADI, 2021). Author’s infographics

Forecast of motor fuel consumption by type of motor fuel by the Russian vehicle fleet until 2050 (MADI, 2021). Author’s infographics

Let us highlight the key technological and economic issues which, in our opinion, constrain the widespread use of natural gas as a fuel for motor vehicles.

When natural gas is used in compressed form:

- The range of vehicles requires from 1–2 (on passenger vehicles) to 10–12 cylinders on trucks and buses, which reduces their passenger and payload capacity. The cost of vehicles in this case increases by 25–30%;

- refueling points (CNG stations) are tied to the pipeline network of gas pipelines, i.e. the area of CNG vehicles use is limited only up to the Urals, excluding northern and other regions, which hinders development of intercity and interregional road transportation, development of a network of refueling stations;

- considerable financial resources need to be invested in the reconstruction (construction) of the production and technical base of road transport enterprises because of the need to meet very strict requirements for fire and explosion safety of cylinders and equipment under high pressure. Thus, according to MADI, costs of transport enterprises for reconstruction of BFS of bus fleets numbering 200–250 units in Moscow region are up to 440 million rubles.;

- due to the need to meet fire and explosion safety requirements for filling stations (CNG filling stations), their location in cities is constrained by the lack of available (unoccupied) land areas.

As a result, due to the small number of CNG vehicles and the intensity of their use, the payback period for investments in CNG infrastructure due to low utilisation and high capital costs increases significantly, requiring higher prices for CNG.

As a result, from the perspective of the consumer (economic entities and households), there is no economically justified motivation to switch motor vehicles to natural gas, because the cost of owning a vehicle on CNG, considering the full life cycle of the vehicle and motor fuel, is significantly higher than that of owning a vehicle on gasoline or diesel fuel.

The solution to the above problems is seen in the transition from the use of natural gas in vehicles in liquefied form (liquefied natural gas — LNG) rather than in compressed form, which will allow

- Increase vehicle range by 2–3 times (LNG — 750–1500 km, CNG — 300–450 km);

- reduce refueling time (the same as for diesel fuel);

- reduce dimensions and weight of fuel tanks (during compression gas volume decreases 200–250 times, during liquefaction and at −161.5 °С — 600 times);

- to locate cryogenic filling stations throughout the country without tying them to the gas pipeline, using cryofillers

- to use LNG regasification for refuelling of CNG-powered vehicles;

- considerably reduce risks of fire and explosion hazard of fuel stations and infrastructure, as the pressure in cryogenic tanks and reservoirs is an order of magnitude lower than that of CNG;

- considerably increase the investment attractiveness of CNG filling station construction and reconstruction of the fuel dispensers.

According to NOVATEK, with an annual mileage of 150,000 km of the vehicle (4×2), a reduction in fuel costs (LNG instead of diesel fuel) at an LNG cost of 28.7 RUB/kg at refuelling can result in an economic effect of 1.15 million RUB per vehicle.

Of course, this must take into account the new challenges associated with:

- Lack of domestic designs of ATVs with LNG engines;

- low number of cryogenic ATVs;

- high cost of domestically produced cryogenic equipment, which leads to higher prices for the final equipment;

- lack of incentives and preferences for manufacturers and consumers of cryogenic equipment;

- lack of state regulation of LNG prices.

Meanwhile, the development of CNG and especially LNG-powered vehicles and refuelling infrastructure allows the use and improvement of technological reserves for the use of compressed or liquefied hydrogen in transport, which may lead to the full decarbonisation of vehicles in the future and ensure high competitiveness of domestic vehicles and refuelling equipment in the world market.

Cover photo: press service of NOVATEK

Comments