22.09.2022

Russian engineers work to reduce carbon footprint in construction

The new polymer coating creates no environmental load.

Photo: TSAGU

Photo: TSAGU

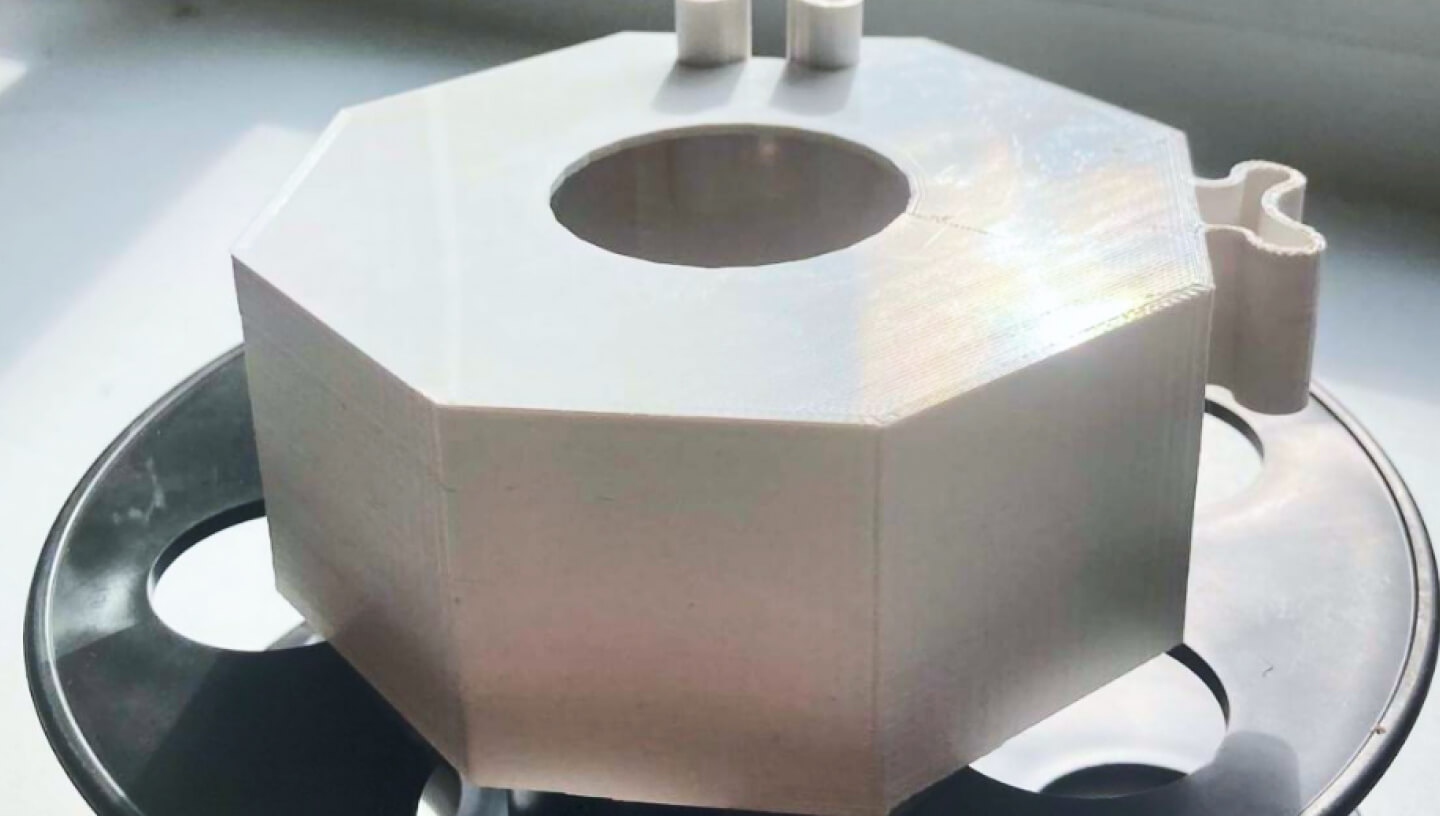

Specialists at Tomsk State University of Architecture and Civil Engineering (TSAGU) have made a prototype of an octagonal paving tile from recycled plastic. According to the scientists, there is no equivalent in Russia, the university’s press service reports.

“A team of scientists from the Department of Engineering Geology, Bridges and Road Structures of Tomsk State University of Architecture and Civil Engineering has used recycled plastic to create durable paving tiles,” the TSASU report says.

According to the authors of the project, the new tiles do not need the traditional method of laying, for which the ground is cut, the formwork is installed and the roots of trees are damaged.

The segments are hollow and have a cutting surface on their lower ends that, when pressed, penetrates the ground and stabilises the soil. The tiles are interlocked with each other to distribute the pressure on the adjacent octagons. The strength of the assembled deck allows both people and vehicles to move over it.

The environmentally friendly installation makes the tiles well suited for creating paths in nature reserves and monument areas.

The recycled plastic material is resistant to temperature fluctuations. It can be used between −50°C and 60°C.

Scientists intend to test the tile in the near future.

Earlier in Russia, it was proposed to use recycled plastic for asphalt paving. The project was presented at the “Strong Ideas for a New Time” forum held in Moscow in the second half of July this year, RIA Novosti reported.

The authors of the initiative presented two concepts. One involves partially replacing bitumen with shredded plastic, which is melted at 170°C and mixed with a bitumen base. This would make the roadbed more durable, prolonging its life by half, as well as reducing the volume of plastic debris.

Another option is to build roads from plastic modules that are laid by crane. This method will reduce the time it takes to lay the tracks to a few weeks. Compacted sand is used as the base for the modular road. Spaces for communications can be laid inside the segments.

The initiators of the project proposed to test the technology on footpaths.

Cover photo: Sergii Petruk / iStock

Comments